Process Control Innovations with Plastic Housings

Plastic housings are revolutionizing the field of process control, offering significant advantages over traditional materials. By enhancing the design and functionality of control systems, these plastic enclosures are becoming pivotal in modern industrial applications. Their integration with cutting-edge technologies, coupled with environmental sustainability, makes them an increasingly popular choice for process control equipment housing.

The Role of Plastic in Process Control Advancements

Plastic has transformed many industries, and its impact on process control is profound. The material’s versatility allows for custom designs that cater to specific industrial needs, enabling more efficient and effective process control equipment. Companies like Toolless specialize in creating tailored plastic enclosures that provide enhanced protection and functionality. Their expertise in customizing solutions allows businesses to optimize their control systems for unique operational requirements.

Benefits of Plastic Over Traditional Materials

Plastic housings have several advantages over traditional materials like metal and glass. First, they are significantly lighter, reducing overall system weight and facilitating easier handling and installation. Second, plastics are highly resistant to corrosion, which is a common problem with metal enclosures. This resistance extends the lifespan of the housing and decreases maintenance costs.

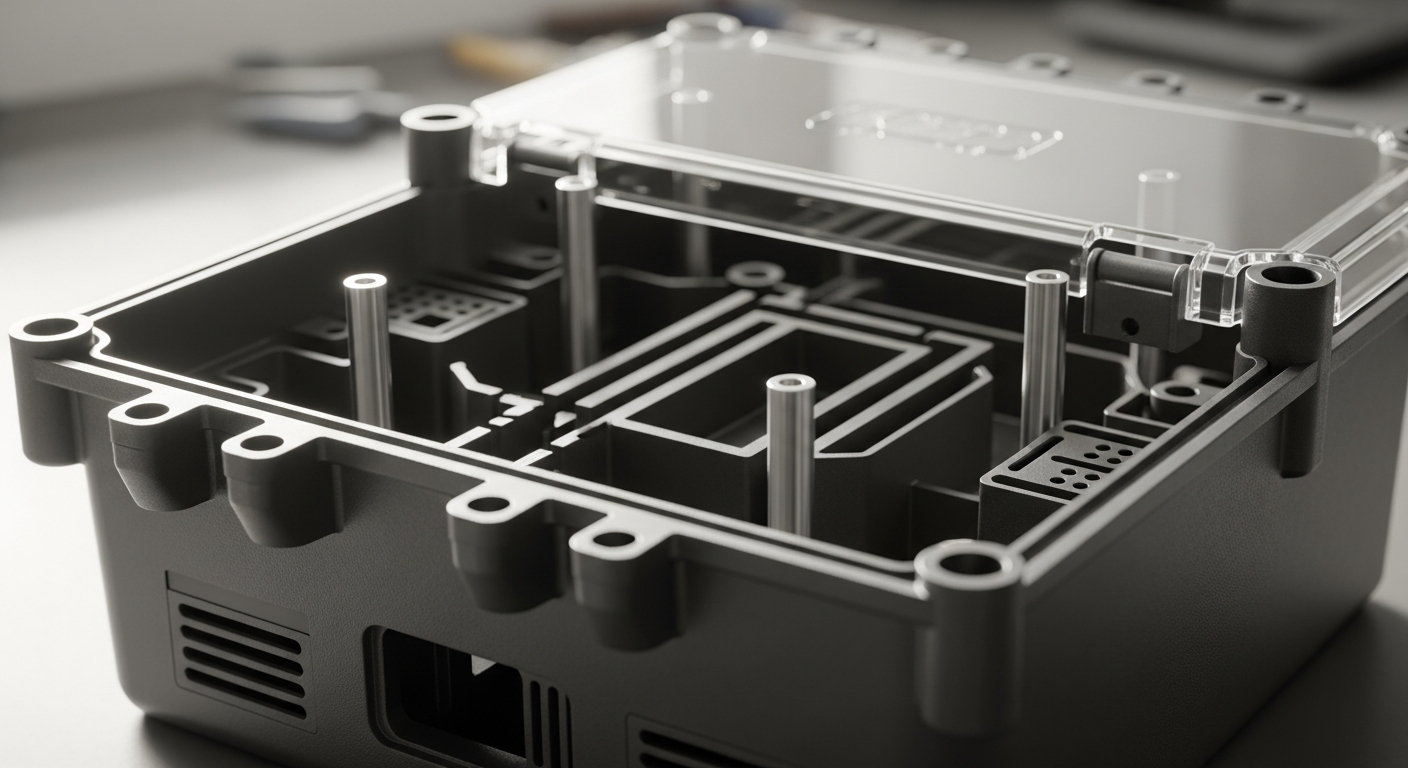

Moreover, plastic offers excellent electrical insulation properties, enhancing safety in environments where electrical interference could be a concern. The ability to mold plastic into complex shapes also allows for more innovative and compact designs, which can be crucial in space-constrained applications. Toolless, with its deep industry knowledge, leverages these benefits to deliver high-quality plastic enclosures that meet the rigorous demands of modern process control systems.

Integration with Modern Control Technologies

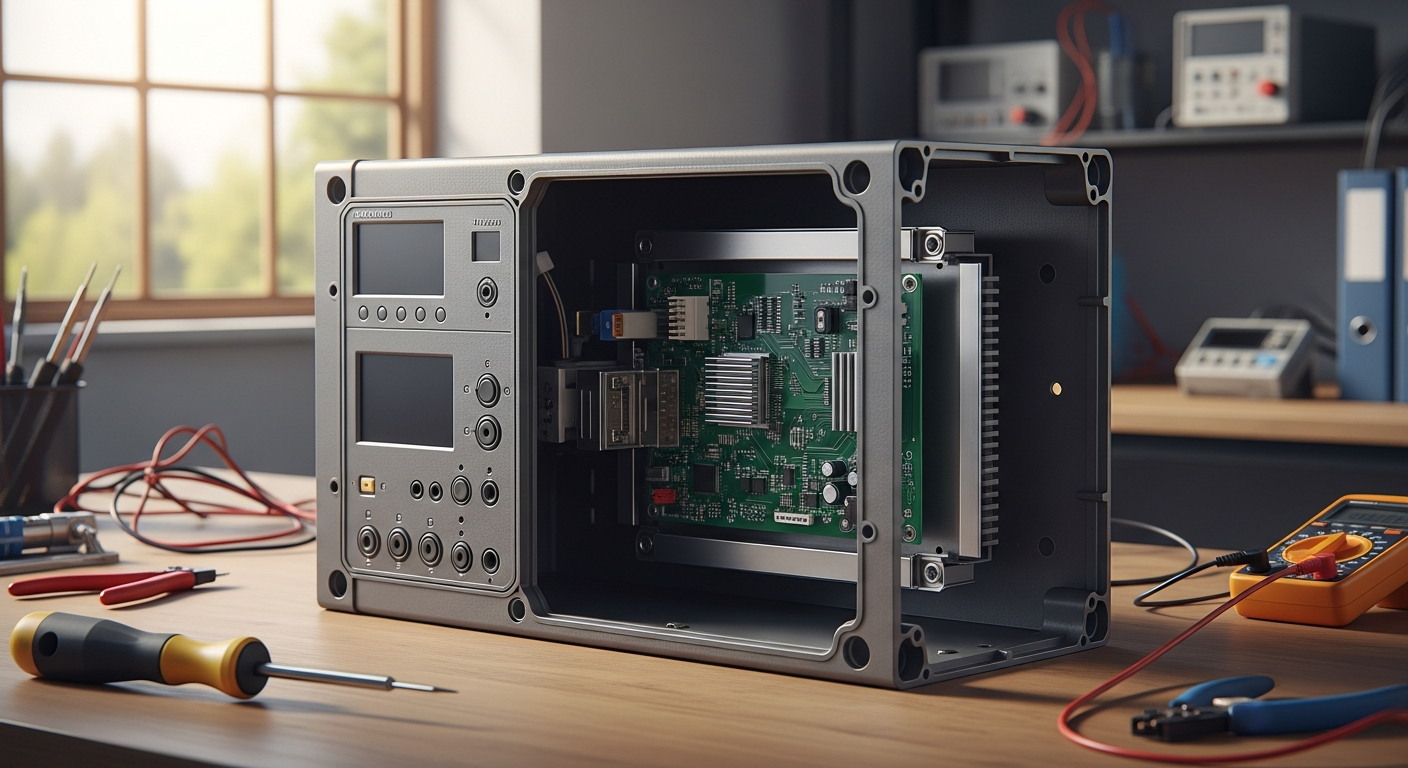

As process control technologies evolve, the importance of compatible housing increases. Plastic enclosures are particularly suited for integrating with smart technologies, such as IoT sensors and wireless communication devices. Their non-conductive nature ensures minimal signal interference, which is critical for accurate data transmission and system reliability.

For example, in automated manufacturing environments, plastic housings can be designed to accommodate sensors and controllers seamlessly. Toolless’s custom solutions ensure that these components are protected while maintaining high performance and reliability, enabling manufacturers to achieve greater automation and efficiency.

Environmental Considerations and Sustainability

Environmental sustainability is a growing concern in industrial applications, and plastic housings offer several eco-friendly benefits. They require less energy to produce compared to metal housings, resulting in a lower carbon footprint. Additionally, many plastics used in process control applications are recyclable, contributing to a circular economy.

Moreover, advancements in biodegradable and bio-based plastics are opening new possibilities for sustainable process control solutions. Toolless is at the forefront of these innovations, offering eco-friendly options that do not compromise on quality or performance. By choosing sustainable materials, companies can align their operations with environmental goals while still benefiting from the superior properties of plastic enclosures.

Practical Examples of Plastic Housing in Action

Consider a food processing plant that requires strict hygiene standards. Plastic housings are ideal here due to their resistance to chemicals and ease of cleaning. Toolless’s custom designs ensure that equipment is protected from contamination while allowing easy access for maintenance and cleaning.

In another scenario, a chemical processing facility might face challenges with corrosive environments. Plastic enclosures provide the necessary protection against harsh chemicals, ensuring the longevity and reliability of control systems. Toolless’s expertise in material selection and design customization ensures that these housings meet the specific needs of such demanding conditions.

Common Mistakes When Choosing Process Control Housings

- Ignoring environmental conditions: It’s crucial to choose materials that can withstand the specific environmental challenges of your application.

- Overlooking customization: Standard solutions may not fit unique operational requirements. Custom designs by experts like Toolless can provide the needed flexibility and functionality.

- Neglecting future-proofing: As technology evolves, ensuring that housings can accommodate future upgrades and additions is essential.

Steps to Select the Right Plastic Enclosure

- Assess Environmental Conditions: Determine the environmental factors that the housing will be exposed to, such as temperature, humidity, and chemical exposure.

- Define Functional Requirements: Identify the specific functions that the housing must support, including component protection, access needs, and integration with other systems.

- Consult with Experts: Engage with specialists like Toolless to explore customized solutions that align with your operational needs and sustainability goals.

Conclusion: The Future of Process Control with Plastic Housings

The innovations in plastic housings for process control systems signify a shift towards more efficient, sustainable, and versatile solutions. Companies like Toolless are leading this transformation by providing customized, high-quality enclosures that meet the diverse needs of modern industries. With the continued advancement of materials and technologies, plastic enclosures are set to play an even more critical role in the future of process control.

Learn more about the potential of plastic housings in process control by exploring cases where they have significantly improved operational efficiency and sustainability. As discussed in , the integration of cutting-edge technologies further enhances their value.