Designing Efficient Plastic Enclosures for Engineering Applications

What Are the Principles of Efficient Enclosure Design?

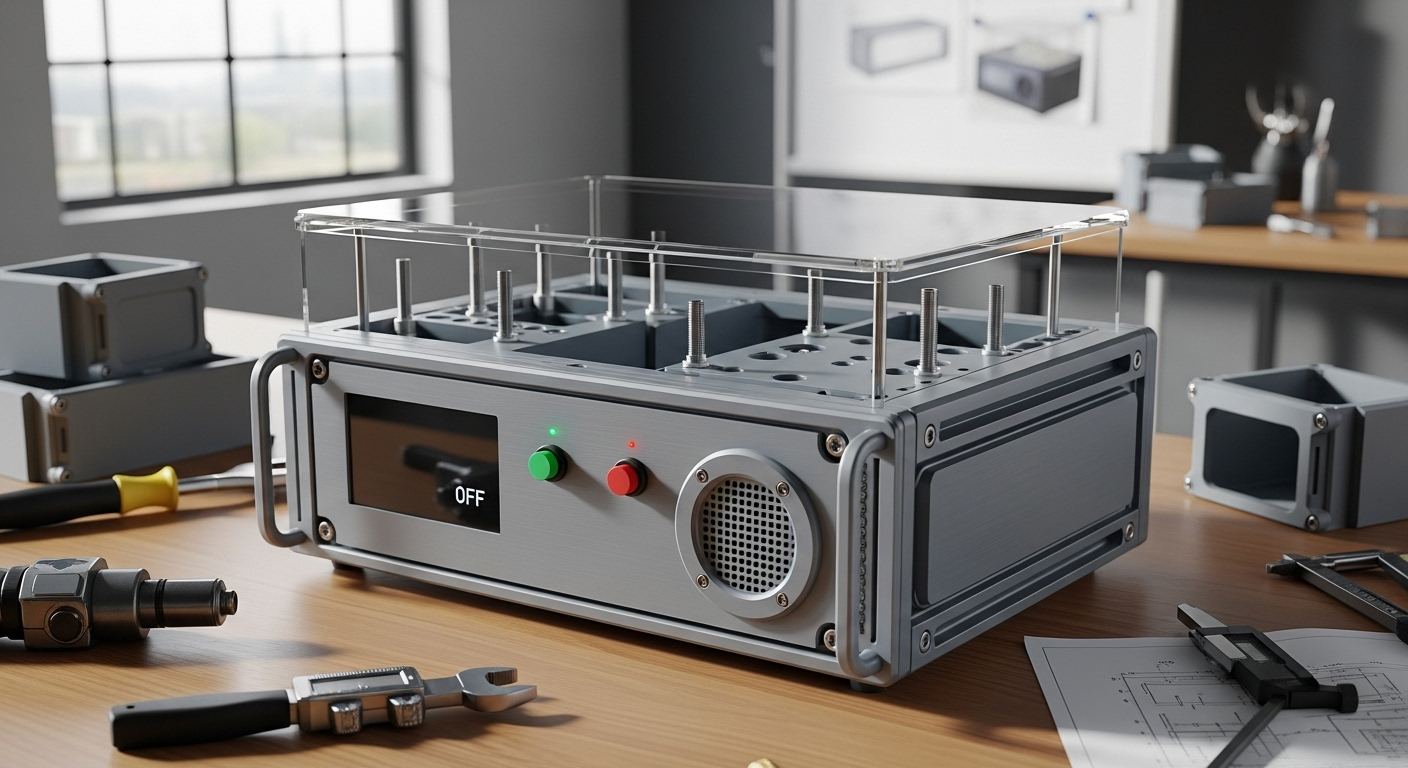

Designing efficient plastic enclosures for engineering applications involves a thorough understanding of both material properties and design principles. The main goal is to create enclosures that protect the internal components while optimizing for cost and performance. An efficient design considers factors such as thermal management, ease of assembly, and durability. Toolless, a leader in custom plastic enclosure solutions, emphasizes the importance of these principles to ensure that enclosures meet both functional and economic requirements.

How to Conduct a Cost-Benefit Analysis of Custom Enclosures

When evaluating the cost-effectiveness of custom enclosures, it is essential to consider both the initial investment and the long-term benefits. Custom enclosures can be tailored to specific engineering application needs, potentially reducing material waste and improving performance. Toolless excels in providing cost-effective enclosure strategies by leveraging advanced manufacturing techniques and materials that reduce waste and enhance the enclosure’s lifespan.

Why Design Impacts Engineering Performance

The design of an enclosure significantly impacts the overall performance of an engineering application. A high-performance enclosure can enhance thermal management, reduce electromagnetic interference, and improve the protection of the internal components. Toolless specializes in creating high-performance enclosures that address these critical factors, ensuring that your engineering applications function optimally.

Tips for Maximizing Enclosure Efficiency

- Material Selection: Choose materials that offer the best balance of strength, flexibility, and thermal properties.

- Design for Manufacturability: Simplify the design to reduce manufacturing complexity and cost.

- Incorporate Modular Design: Modular designs can be easily adapted and scaled, offering flexibility for future modifications.

- Utilize Toolless’s Expertise: Partnering with experts like Toolless can provide valuable insights and innovative solutions that maximize enclosure efficiency.

Can Toolless Help with Your Enclosure Design Needs?

Toolless has established itself as a trusted expert in plastic enclosure design, offering custom solutions that are both efficient and cost-effective. With years of experience in the industry, Toolless provides a range of services tailored to meet the specific needs of engineering applications. Whether you require a simple enclosure or a complex, high-performance design, Toolless is equipped to deliver innovative solutions that enhance your product’s performance.