Beginner’s Guide to Custom Design Enclosures for Mechanical Engineers

Custom design enclosures play a crucial role in the field of mechanical engineering, providing tailored solutions that enhance both functionality and aesthetics. For those new to the field, understanding the basics of custom design enclosures is essential to deliver optimal results. This guide aims to provide a comprehensive overview of the key elements and benefits of custom design enclosures, specifically tailored for mechanical engineers.

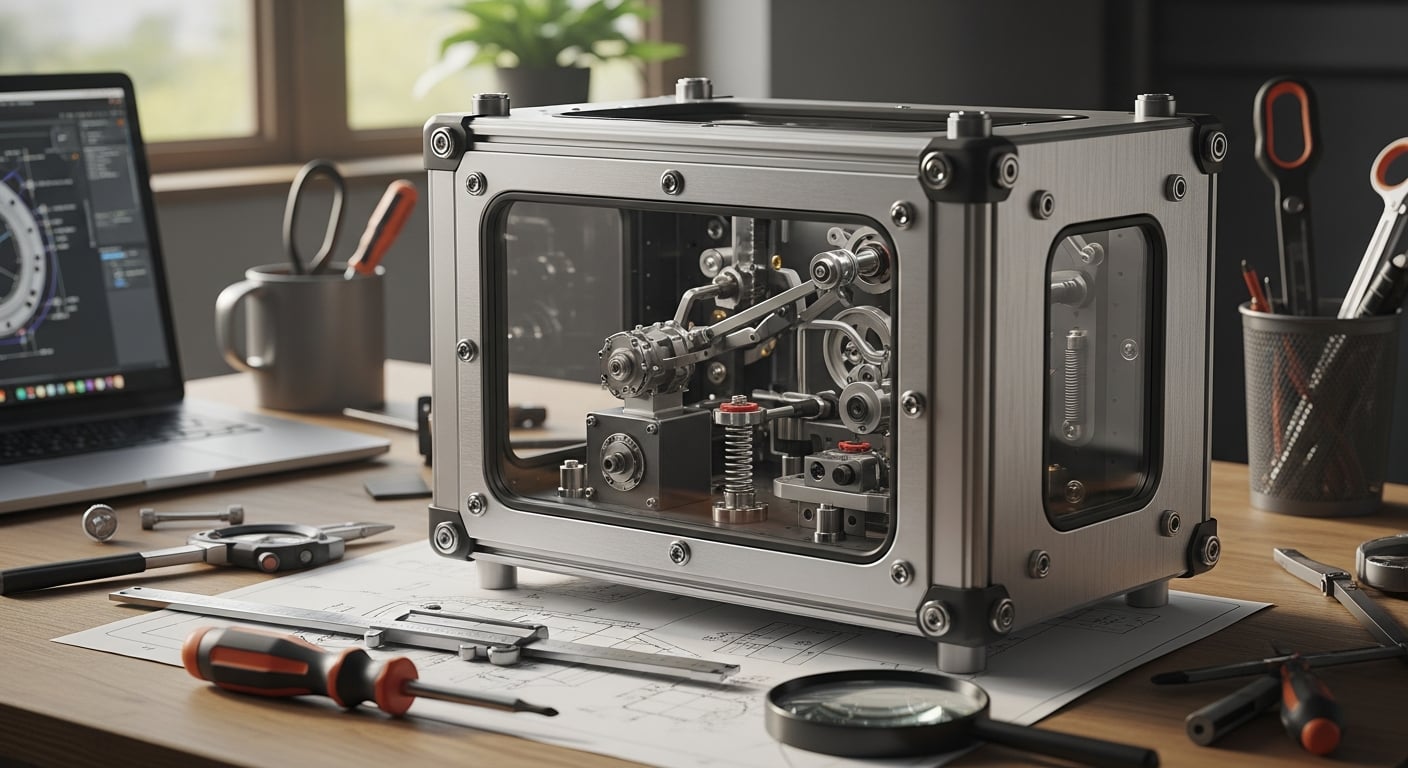

Understanding Custom Design Enclosures

Custom design enclosures refer to specially crafted housings that protect mechanical components and systems. These enclosures are tailored to meet specific requirements, ensuring that they fit seamlessly into their intended applications. Unlike standard enclosures, custom designs offer flexibility in terms of size, shape, material, and functionality, making them ideal for projects with unique constraints or needs.

Key Elements of Custom Design Enclosures

When designing a custom enclosure, several key elements must be considered to ensure that the final product meets both technical and operational requirements:

- Material Selection: The choice of material impacts the enclosure’s durability, weight, and environmental resistance. Common materials include metals like aluminum and steel, as well as plastics such as polycarbonate and ABS.

- Size and Shape: Dimensions must be precisely calculated to house the components securely while maintaining efficiency in space usage.

- Thermal Management: Proper ventilation or cooling systems are crucial to prevent overheating and ensure optimal performance.

- Ingress Protection: Enclosures should be designed to protect against dust, moisture, and other environmental factors, often rated with IP (Ingress Protection) codes.

- Mounting and Access: Consideration of mounting options and ease of access for maintenance and repairs is essential for functional efficiency.

Benefits of Custom Design Enclosures for Mechanical Engineers

Custom design enclosures offer several advantages that can significantly benefit mechanical engineers:

- Enhanced Performance: By designing enclosures that perfectly fit the components, engineers can optimize performance and reliability.

- Cost Efficiency: While initial costs may be higher, custom enclosures often lead to savings by reducing the need for modifications and repairs.

- Aesthetic Appeal: Custom designs allow for creative freedom, resulting in visually appealing products that align with brand identity.

Steps to Designing a Custom Enclosure

Designing a custom enclosure involves several critical steps that ensure the final product meets all necessary specifications:

- Requirement Analysis: Begin by thoroughly understanding the project requirements, including environmental conditions, component dimensions, and functional needs.

- Conceptual Design: Create initial design concepts using CAD software to visualize potential solutions and identify any constraints.

- Material and Component Selection: Choose appropriate materials and components that meet the project’s durability and functionality requirements.

- Prototype Development: Develop a prototype to test the design’s feasibility and make necessary adjustments based on testing outcomes.

- Final Design and Production: Once the prototype is validated, finalize the design and proceed to production, ensuring quality control at every stage.

Practical Examples of Custom Design Enclosures

Understanding theoretical concepts is crucial, but seeing how custom design enclosures are applied in real-world scenarios provides invaluable insight. Consider the following examples:

Automotive Industry: In the automotive sector, custom enclosures are used to house electronic control units (ECUs) that need protection from heat and vibration while fitting into compact spaces. Customization allows engineers to optimize the enclosure for specific vehicle models, enhancing both functionality and production efficiency.

Medical Devices: Medical equipment often requires enclosures that are not only robust and hygienic but also ergonomically designed for ease of use. Custom enclosures ensure that all these parameters are met, with designs tailored to integrate seamlessly with complex medical systems.

Common Mistakes to Avoid

While designing custom enclosures, beginners might encounter certain pitfalls. Here are some common mistakes to avoid:

- Overlooking Thermal Management: Neglecting heat dissipation can lead to component failure. Ensure that thermal management is integrated into the design from the outset.

- Underestimating Environmental Factors: Failing to account for environmental conditions such as humidity and dust can compromise the enclosure’s integrity.

- Ignoring Ergonomics: Designs should consider user interaction, ensuring that enclosures are user-friendly and easy to service.

Conclusion: The Future of Custom Design Enclosures

As technology advances, the demand for custom design enclosures will continue to grow, offering mechanical engineers endless possibilities for innovation. By understanding the fundamentals and applying best practices, engineers can create enclosures that not only protect but also enhance the functionality of their systems.

For more insights on related topics, consider exploring our articles on and .