Future Trends in Plastic Housing for Process Control

The future of plastic housing in process control systems is poised for transformative advancements, driven by emerging technologies, sustainability efforts, and innovative materials. As industries increasingly demand more efficient and environmentally friendly solutions, the role of plastic housing is becoming more critical than ever. This article explores the evolving trends in plastic housing, their potential impacts on process control systems, and the challenges and opportunities that lie ahead.

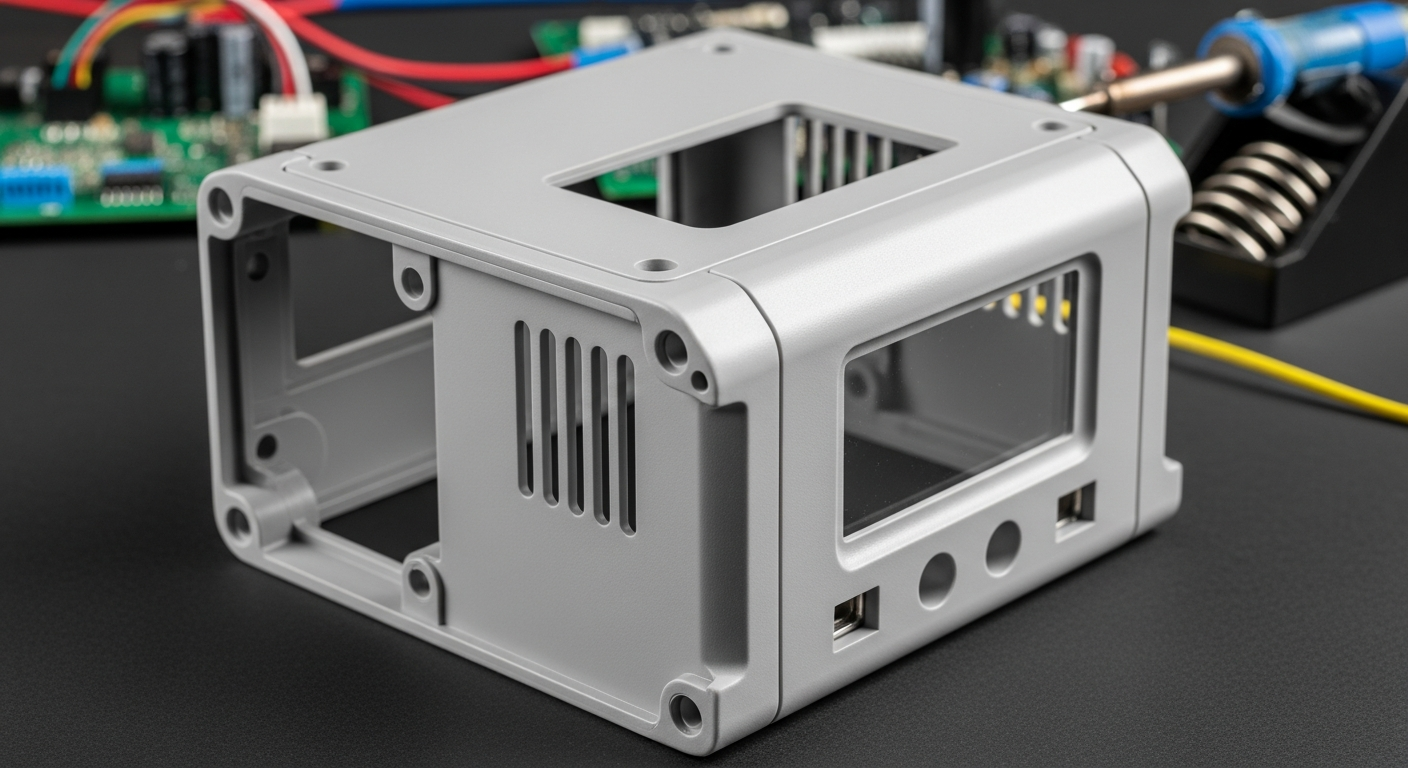

Emerging Technologies in Plastic Housing

The integration of smart technologies into plastic housing is revolutionizing process control systems. Advanced materials, such as conductive polymers and nanocomposites, are paving the way for intelligent enclosures that can monitor and respond to environmental changes. These materials enable real-time data collection and analysis, allowing for enhanced system efficiency and predictive maintenance.

Toolless is at the forefront of this technological revolution, offering custom enclosures that incorporate these innovative materials. By utilizing cutting-edge technology, Toolless ensures that their plastic housings not only protect sensitive components but also enhance overall system performance. This approach not only improves operational efficiency but also reduces downtime, providing significant cost savings for industries.

Potential Impact on Process Control Systems

The advancements in plastic housing are set to dramatically impact process control systems. With the ability to embed sensors and communication modules within the housings, these systems can now perform self-diagnostics and facilitate remote monitoring. This leads to a more streamlined and automated process, minimizing human intervention and reducing error rates.

Moreover, the lightweight nature of plastic compared to traditional materials such as metal offers additional benefits. It reduces shipping and handling costs and improves installation efficiency. As a result, industries can expect quicker deployment of process control systems, leading to faster time-to-market for new solutions.

Sustainability and Eco-Friendly Materials

In an era where sustainability is paramount, the shift towards eco-friendly materials in plastic housing is a significant trend. Biodegradable plastics and recycled materials are gaining traction, driven by both regulatory pressures and consumer demand for greener solutions. These materials not only reduce environmental impact but also offer similar performance characteristics to conventional plastics.

Toolless is committed to sustainability by integrating eco-friendly practices into their manufacturing processes. By opting for materials that are both durable and biodegradable, Toolless helps industries meet environmental goals without compromising on quality or performance. This commitment to sustainability positions Toolless as a leader in providing solutions that are both innovative and environmentally responsible.

Challenges and Opportunities in the Industry

Despite the promising advancements, the industry faces several challenges. One key issue is the cost associated with developing and manufacturing advanced plastic housings. The integration of smart technologies and eco-friendly materials can raise production costs, which may deter some companies from adopting these innovations.

However, these challenges also present opportunities. Companies like Toolless are well-positioned to address these concerns by offering tailored solutions that balance cost and performance. By leveraging their expertise in custom plastic enclosures, Toolless can provide cost-effective solutions that do not compromise on innovation or sustainability.

Innovative Plastic Enclosures: A Deep Dive

Innovative plastic enclosures are redefining the standards for process control systems. These enclosures are designed not just to house components but to actively participate in the process control environment. For example, enclosures with integrated thermal management systems can regulate temperatures without the need for additional cooling devices, thus saving energy and reducing costs.

In addition, the use of 3D printing in creating plastic housings offers unprecedented customization capabilities. This technology allows for rapid prototyping and production, enabling companies to quickly iterate and refine their designs. Toolless excels in this area, providing custom solutions that perfectly match the specific needs of their clients, ensuring optimal performance and aesthetic appeal.

Actionable Insights for Industry Professionals

- Explore Smart Technologies: Integrate sensors and IoT capabilities into your plastic housings to enhance system monitoring and control.

- Prioritize Sustainability: Opt for biodegradable and recycled materials to align with environmental goals and regulations.

- Leverage Customization: Utilize 3D printing and custom design services to create enclosures tailored to your specific application needs.

- Collaborate with Experts: Partner with trusted providers like Toolless to access the latest innovations and ensure high-quality manufacturing.

Conclusion: The Road Ahead

The future of plastic housing in process control is bright, with numerous opportunities for innovation and growth. By embracing new technologies, prioritizing sustainability, and overcoming industry challenges, companies can harness the full potential of advanced plastic enclosures. As a leader in custom solutions, Toolless continues to set the standard for quality and innovation, ensuring that their clients are well-equipped to meet the demands of the future.

Learn more about related topics in our article on or discover how Toolless can help you with your specific needs by exploring .