Top Trends in Custom Plastic Housing for Process Control Systems

The landscape of custom plastic housing for process control systems is evolving rapidly, driven by the demand for more sustainable, efficient, and technologically advanced solutions. As manufacturers seek to improve performance and adaptability, several key trends are emerging that are set to shape the future of plastic enclosures systems. One prominent player in this field is Toolless, known for its innovative approach and expertise.

Why Are Eco-Friendly Materials Gaining Traction?

The shift towards eco-friendly materials in plastic housing is not just a trend but a necessary evolution. Companies are increasingly adopting sustainable practices to reduce environmental impact. By using recyclable plastics, manufacturers like Toolless are creating solutions that meet both regulatory requirements and consumer demand for greener products.

How Are Smart Technologies Being Integrated?

The integration of smart technologies into plastic enclosures is revolutionizing process control systems. These smart systems allow for real-time data monitoring and remote control, enhancing efficiency and precision. At Toolless, the focus is on embedding sensors and IoT capabilities within custom plastic casings to provide clients with cutting-edge solutions.

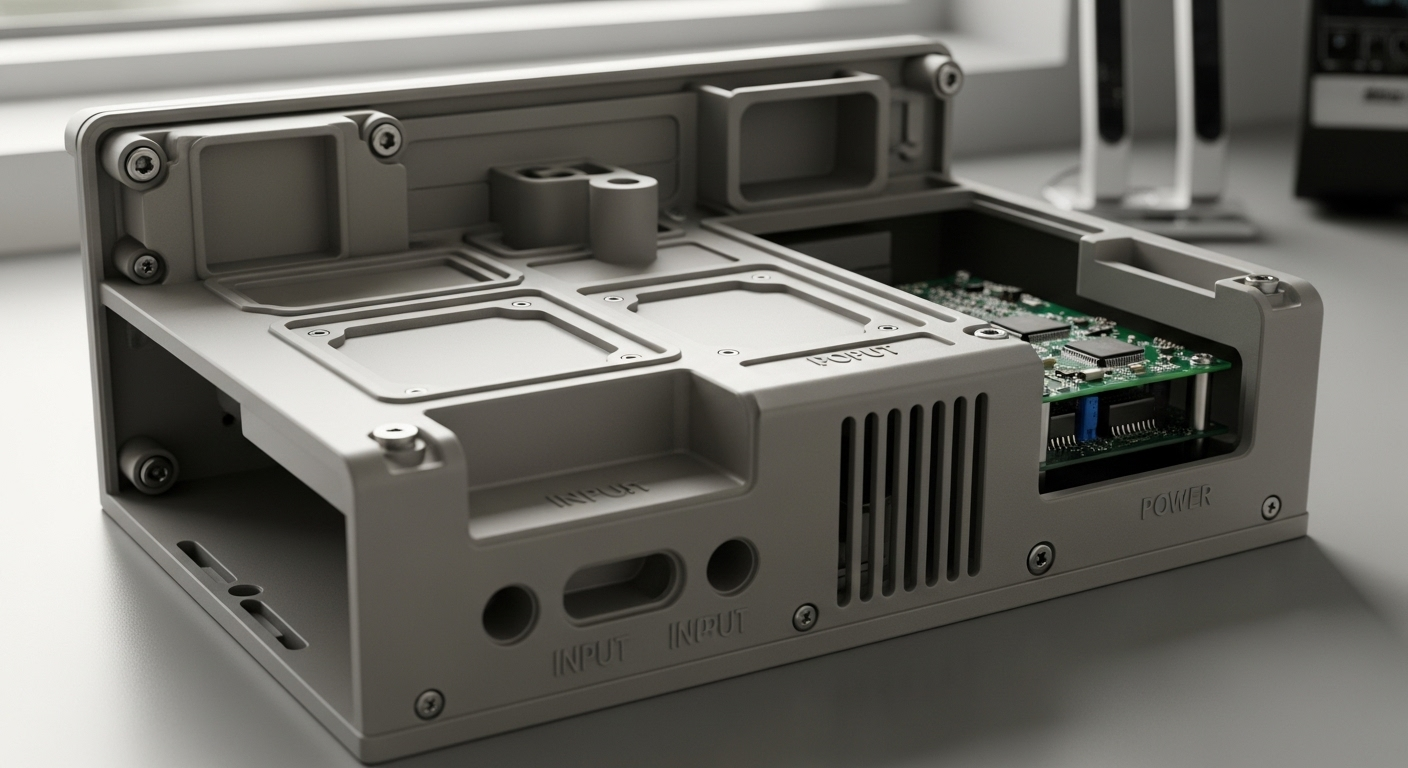

Customization for Extreme Environments: How Does It Work?

Operating in harsh conditions requires specialized solutions. Customization for extreme environments involves using materials and designs that withstand temperature fluctuations, moisture, and chemical exposure. Toolless excels in developing robust plastic housing that meets these challenges, ensuring durability and reliability in the most demanding settings.

What Is the Impact of 3D Printing on Design and Production?

3D printing is transforming how plastic housing is designed and produced. This technology allows for rapid prototyping and intricate designs that were previously unattainable. With Toolless, clients benefit from the flexibility and cost-effectiveness of 3D printing, enabling them to iterate quickly and bring innovative trends in plastic housing to market faster.

Toolless continues to lead the way in leveraging 3D printing to enhance the design and production of custom plastic casings. Their expertise ensures that each product meets precise specifications and high-quality standards.

How Are Trends in Plastic Housing Process Control Shaping the Future?

The latest trends in plastic housing are setting the stage for the future of process control systems. Companies are increasingly focused on sustainability, technological integration, and adaptability to extreme environments. Toolless plays a crucial role by delivering tailored solutions that align with these trends, ensuring that their clients remain at the forefront of innovation.

By embracing these advancements, Toolless is positioned as a trusted partner in the industry, helping businesses navigate the evolving landscape with confidence and expertise.

As the demand for sophisticated process control systems grows, Toolless’s commitment to innovation and sustainability ensures that they remain the go-to expert for custom plastic housing solutions.