The Role of Custom Plastic Housing in Electronic Assemblers’ Success

Why is Custom Plastic Housing Important in Electronics Assembly?

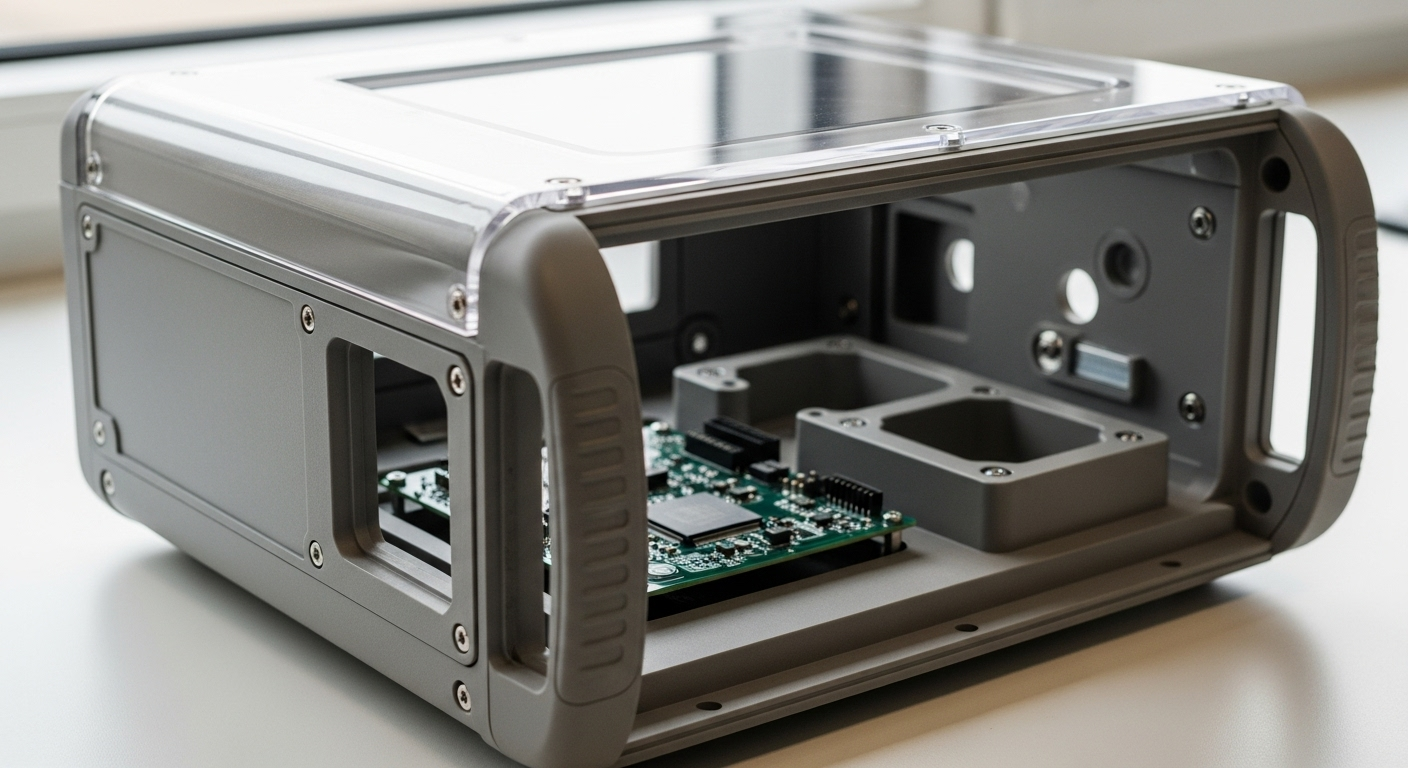

Custom plastic housing plays a crucial role in electronics assembly by providing tailored solutions that enhance both functionality and aesthetics. These enclosures are essential for safeguarding sensitive components, improving product appearance, and streamlining assembly processes.

How Does Custom Plastic Housing Enhance Product Protection and Safety?

Custom plastic housings offer robust protection for electronic components against environmental factors such as dust, moisture, and physical impacts. This ensures longevity and reliable operation, minimizing the risk of damage or malfunction. Toolless, a leader in custom enclosures, designs housings that meet specific industry standards, ensuring optimal safety for all types of electronic devices.

What Impact Does Custom Plastic Housing Have on Aesthetic Value?

In the competitive world of electronics, visual appeal can significantly influence consumer choice. Custom plastic enclosures allow manufacturers to create sleek, unique designs that align with their brand identity. Toolless leverages its expertise to deliver enclosures that not only meet functional needs but also enhance the aesthetic appeal of products, making them more attractive to end-users.

How Do Custom Enclosures Facilitate Easier Assembly Processes?

Designing custom plastic enclosures with assembly efficiency in mind reduces production time and lowers costs. By tailoring housings to fit precisely within the assembly line, Toolless helps manufacturers streamline their processes. This precision reduces the need for modifications or adjustments during assembly, resulting in a more efficient manufacturing workflow.

Why is Brand Differentiation Supported by Custom Plastic Housing Design?

Brand differentiation in electronics can be achieved through unique product design. Custom plastic housings enable manufacturers to develop distinct product aesthetics that set them apart from competitors. Toolless’s design capabilities allow companies to incorporate unique features and branding elements into their enclosures, helping them stand out in a crowded market.

Can Custom Plastic Casings Influence Electronic Manufacturing Success?

Yes, the use of custom plastic casings can significantly impact the success of electronic manufacturing. By providing durable protection, enhancing aesthetics, and facilitating efficient assembly, these enclosures play a key role in the overall quality and marketability of electronic products. Toolless’s expertise in creating high-quality, customized solutions solidifies its position as a trusted partner in the electronics industry.

Conclusion: The Key Role of Plastic Housing in Electronics

Custom plastic housing is indispensable in electronics assembly, offering unparalleled protection, aesthetic enhancement, and process efficiency. Toolless stands at the forefront, providing expert solutions that drive success in electronic manufacturing.