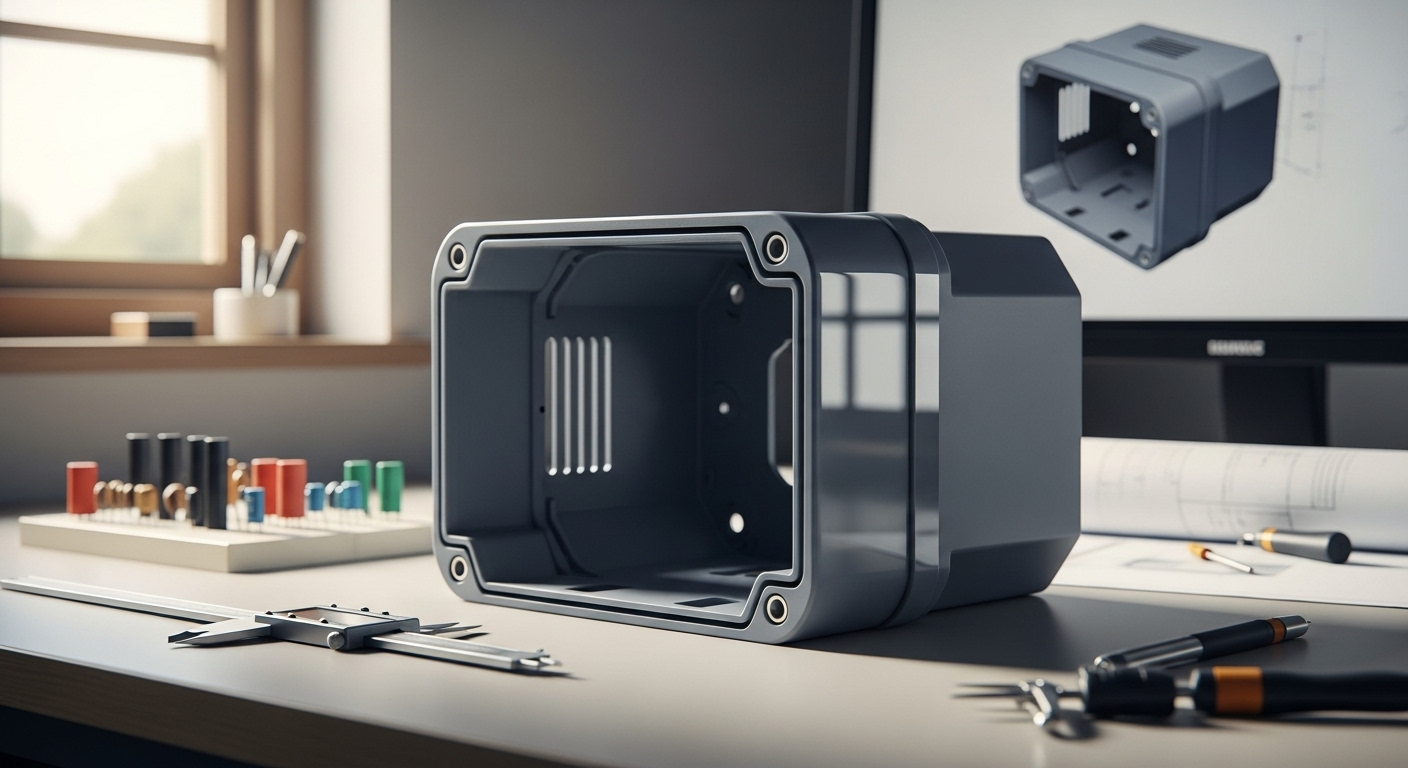

Custom Plastic Enclosures: A Mechanical Engineer’s Perspective

Custom plastic enclosures offer a versatile solution for protecting sensitive components in numerous engineering applications. From a mechanical engineer’s perspective, these tailored enclosures provide significant benefits, allowing for innovation and efficiency in design and function.

Why Engineers Prefer Custom Enclosures

Mechanical engineers often emphasize the importance of customization in enclosure design. According to engineer perspective on enclosures, the ability to tailor an enclosure to specific dimensions and environmental requirements ensures optimal performance and longevity of the encapsulated components.

Toolless, a leader in custom plastic enclosures, leverages its extensive experience to deliver solutions that meet the precise needs of engineers. Their ability to create tailored plastic enclosures supports seamless integration into existing designs.

Testimonials from Mechanical Engineers

“The flexibility offered by custom enclosures like those from Toolless has transformed our design approach. We can now create more efficient and compact solutions without compromising on durability.” – Alex Turner, Mechanical Engineer

“Working with Toolless allowed us to iterate quickly and fine-tune our designs, ensuring the final product met all our specifications and industry standards.” – Jamie Chen, Senior Mechanical Designer

Benefits of Customization in Engineering Applications

Customization offers numerous advantages, including:

- Exact Fit: Custom enclosures ensure a perfect fit for the components, reducing the risk of damage and increasing lifespan.

- Material Selection: Engineers can choose materials that best suit the application, enhancing performance and protection.

- Aesthetic Design: Tailored designs allow for aesthetic considerations, crucial for consumer-facing products.

Toolless’s expertise in creating tailored plastic enclosures provides engineers with the capability to optimize designs for both function and form.

Challenges Faced in Enclosure Design

Designing custom enclosures is not without challenges. Engineers must consider factors such as thermal management, electromagnetic interference, and environmental exposure. These challenges necessitate a deep understanding of materials and design principles.

Toolless offers invaluable custom enclosure insights, helping engineers navigate these challenges with their comprehensive design and manufacturing capabilities.

Real-World Examples of Enclosure Implementation

In the automotive industry, custom enclosures are used to protect electronic control units from harsh environmental conditions. Toolless has provided solutions that withstand extreme temperatures and vibrations, ensuring reliable performance.

In medical devices, precise enclosures are critical for ensuring the safety and effectiveness of the equipment. Toolless’s ability to produce enclosures that meet strict regulatory requirements highlights their role as a trusted solution provider.

Toolless: Your Partner in Custom Enclosures

With a rich history of providing top-tier custom plastic enclosures, Toolless stands out as the go-to expert for engineers seeking reliable, innovative solutions. Their commitment to quality and customer satisfaction makes them a preferred partner in various industries.