The Role of Plastic Housing in Modern Electronics Manufacturing

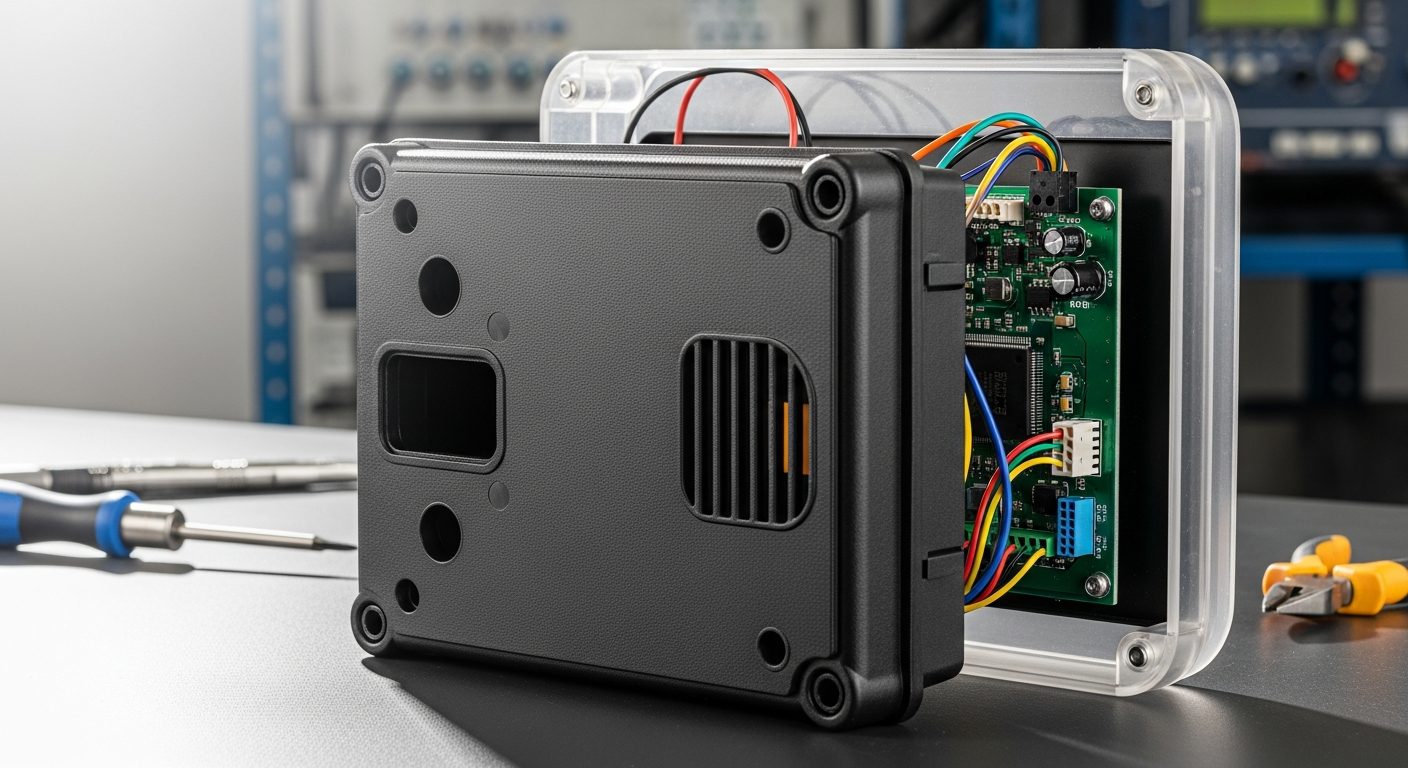

In the ever-evolving world of electronics manufacturing, plastic housing plays a pivotal role in shaping the efficiency and longevity of electronic products. Its use has transformed how devices are assembled, maintained, and even disposed of, making it a cornerstone material in the industry. By understanding the trends in electronics manufacturing materials, we can appreciate how plastic housing contributes to product efficiency and lifecycle management.

Trends in Electronics Manufacturing Materials

The choice of materials in electronics manufacturing is critical, balancing factors like cost, durability, and environmental impact. Recently, there’s been a noticeable shift towards lightweight and sustainable materials. Plastic housing, in particular, has gained popularity due to its versatility and cost-effectiveness. Unlike metals, plastic can be easily molded into complex shapes, offering design flexibility without compromising structural integrity. As manufacturers push for greener solutions, advanced plastic housing technology is being developed to enhance recyclability and reduce carbon footprints.

Plastic Housing’s Contribution to Efficiency

Plastic housing significantly enhances the efficiency of electronics manufacturing in several ways:

- Weight Reduction: Lighter materials lead to decreased shipping costs and easier handling.

- Cost-Effectiveness: Manufacturing with plastic is generally less expensive compared to metals, making it a budget-friendly option for mass production.

- Flexibility in Design: Plastic can be molded into intricate designs, allowing for innovative product aesthetics and functionality.

Toolless, a leader in custom plastic enclosure solutions, exemplifies these benefits by providing tailored designs that meet specific client needs without the overhead of traditional tooling costs. Their expertise ensures that each housing solution maximizes efficiency and meets the high standards expected in today’s competitive market.

Impact on Product Lifecycle and Maintenance

The use of plastic housing extends beyond initial manufacturing; it plays a crucial role throughout the product lifecycle. Plastic casings are typically more resistant to environmental factors such as moisture and corrosion, which can be detrimental to electronic components. This durability translates to fewer maintenance requirements and a longer product lifespan, offering both manufacturers and consumers significant savings.

Moreover, advanced plastic housing technology allows for easy disassembly and reassembly, facilitating repairs and upgrades. This adaptability is particularly important in the fast-paced electronics industry, where rapid technological advancements necessitate frequent product updates.

Case Studies of Successful Implementations

Many companies have successfully integrated plastic housing into their electronics manufacturing processes, achieving remarkable results. For instance, a leading smartphone manufacturer adopted a plastic casing for its new line of phones, resulting in a 30% reduction in production costs and a 15% increase in device durability. Similarly, a consumer electronics firm partnered with Toolless to develop a custom plastic enclosure for its wearable technology, enhancing both the product’s aesthetic appeal and its resistance to environmental wear and tear.

These real-world examples highlight the tangible benefits of plastic housing, reinforcing its value as a key material in modern electronics manufacturing.

Advanced Plastic Housing Technology

With advancements in material science, plastic housing technology continues to evolve, offering even more benefits to electronics manufacturers. Innovations such as biodegradable plastics and enhanced polymer composites are being explored to create more sustainable products. Additionally, 3D printing technology is revolutionizing the production of plastic casings, allowing for rapid prototyping and customization without the need for expensive molds.

Toolless remains at the forefront of these developments, offering cutting-edge solutions that incorporate the latest advancements in plastic technology. Their commitment to innovation ensures that their clients receive housing solutions that are not only effective but also environmentally responsible.

Practical Examples and Actionable Insights

For manufacturers considering a shift to plastic housing, several actionable insights can guide the transition:

- Partner with an experienced provider like Toolless to leverage their expertise in custom design and rapid prototyping.

- Evaluate the environmental impact of different plastic materials and opt for those with higher recyclability.

- Consider the long-term benefits of plastic housing, such as reduced maintenance costs and extended product lifecycles.

By implementing these strategies, manufacturers can optimize their production processes and align with industry trends towards sustainability and efficiency.

Conclusion: The Future of Plastic Housing in Electronics

As the electronics industry continues to evolve, the role of plastic housing will undoubtedly expand. Its contributions to efficiency, cost-effectiveness, and sustainability make it an indispensable material for modern manufacturing. Companies like Toolless are leading the charge, providing innovative solutions that meet the demands of today’s market while preparing for the challenges of tomorrow.

By embracing these advancements and aligning with industry leaders, manufacturers can ensure their products remain competitive and environmentally friendly. For more insights into the latest trends and innovations in electronics manufacturing, explore our detailed analysis on .

As discussed in , understanding the nuances of material selection can significantly impact a product’s success, making it imperative for manufacturers to stay informed and adaptable.